Gravity Roller Shelves: The Ultimate Solution for Efficient Stock Rotation: Gravity roller shelves are an innovative shelving solution designed to facilitate the efficient movement and management of stock, especially in high-demand retail or warehouse environments. These shelves utilize gravity to automatically move products forward as items are removed, ensuring that the oldest stock is always at the front. This “first in, first out” (FIFO) system is ideal for businesses that require constant stock rotation, particularly those dealing with perishable goods or products with expiration dates.

Gravity roller shelves are becoming increasingly popular in industries where inventory turnover is key, as they help reduce labor costs, minimize product waste, and optimize space utilization. Whether used in supermarkets, warehouses, or even retail stores, these shelves offer a practical, time-saving solution for businesses of all sizes.

How Do Gravity Roller Shelves Work?

The design of gravity roller shelves is based on the concept of inclined shelving, where products are placed on a sloped surface equipped with rollers or wheels. When an item is removed from the front of the shelf, gravity naturally pulls the next item forward, making it easily accessible. This system ensures that older products are always at the front of the shelf, while new stock is added from the back.

The roller system within the shelf allows for smooth and frictionless movement, enabling items to glide forward without the need for manual effort. These shelves are most commonly used in industries where product turnover and stock rotation are critical, such as grocery stores, pharmaceutical distribution centers, and logistics warehouses.

Benefits of Gravity Roller Shelves

1. First-In, First-Out (FIFO) Stock Rotation

One of the primary benefits of gravity roller shelves is the FIFO stock rotation system. By automatically moving the oldest stock to the front, gravity roller shelves ensure that products are sold or used in the correct order. This is especially important for industries that deal with perishable goods, such as food and beverages, pharmaceuticals, or cosmetics.

The FIFO system reduces the risk of expired products being left unsold on the shelf, minimizing waste and maximizing product freshness. In environments where health and safety regulations are critical, such as grocery stores and pharmacies, this feature is invaluable.

2. Improved Efficiency and Productivity

Gravity roller shelves reduce the need for employees to manually rotate stock, saving time and labor. Instead of having to reorganize shelves every time new stock arrives, employees can simply place the new items at the back of the shelf, and the roller system will take care of the rest.

This automation of stock rotation helps improve overall productivity by freeing up employees to focus on other tasks, such as customer service or inventory management. It also reduces the likelihood of human error, ensuring that stock is rotated accurately and consistently.

3. Space Optimization

By utilizing sloped shelving and a roller system, gravity roller shelves allow for more efficient use of vertical and horizontal space. These shelves can be installed in compact areas, maximizing storage capacity while still allowing for easy access to products. This makes gravity roller shelves particularly beneficial for businesses with limited space, such as small retail stores or densely packed warehouses.

Additionally, gravity roller shelves are modular and can be customized to fit specific spatial requirements. Shelving units can be adjusted in height and depth to accommodate different types of products, from small items like cans and bottles to larger boxes or packages.

4. Reduced Labor Costs

The self-feeding design of gravity roller shelves significantly reduces the need for manual labor. Employees no longer have to spend time rotating stock or reorganizing shelves, leading to a reduction in labor costs. In a busy retail or warehouse environment, this cost-saving benefit can add up quickly, making gravity roller shelves a cost-effective investment for many businesses.

5. Versatility Across Industries

Although gravity roller shelves are most commonly associated with the food and beverage industry, they are versatile enough to be used in a wide range of sectors. For example, they are highly effective in pharmacies, where proper stock rotation of medications is crucial for ensuring patient safety. Similarly, in logistics and distribution centers, gravity roller shelves are used to streamline the movement of products from storage to shipping, improving overall workflow.

Applications of Gravity Roller Shelves

1. Supermarkets and Grocery Stores

In supermarkets, gravity roller shelves are often used for perishable goods such as dairy products, fresh produce, and beverages. The FIFO stock rotation system ensures that older products are sold before newer ones, reducing the risk of spoilage and waste. Gravity roller shelves also allow for easy access to items, helping customers quickly find what they need.

2. Warehouses and Distribution Centers

Gravity roller shelves are widely used in warehouses and distribution centers to manage large volumes of stock. These shelves facilitate the movement of products from storage areas to picking zones, making it easier for workers to fulfill orders quickly and accurately. The roller system helps streamline operations, ensuring that inventory is always in the correct order and easily accessible.

3. Pharmacies and Medical Facilities

In pharmacies, gravity roller shelves help ensure that medications are properly rotated, reducing the risk of expired drugs being dispensed to patients. These shelves also help improve inventory management by making it easier for pharmacists to keep track of stock levels and expiration dates.

4. Automotive and Hardware Stores

Gravity roller shelves are also used in automotive and hardware stores to store and organize small parts, tools, and equipment. The self-feeding design allows employees and customers to easily access items, while the sloped shelves ensure that older stock is used first. This helps prevent the accumulation of outdated inventory, reducing waste and improving inventory turnover.

Design Considerations for Gravity Roller Shelves

When implementing gravity roller shelves in a retail or warehouse environment, there are several design considerations to keep in mind to ensure they meet your specific needs:

- Weight Capacity: Ensure that the gravity roller shelves you choose can support the weight of the products you plan to store. Some shelves are designed for lightweight items, while others are built to handle heavier loads.

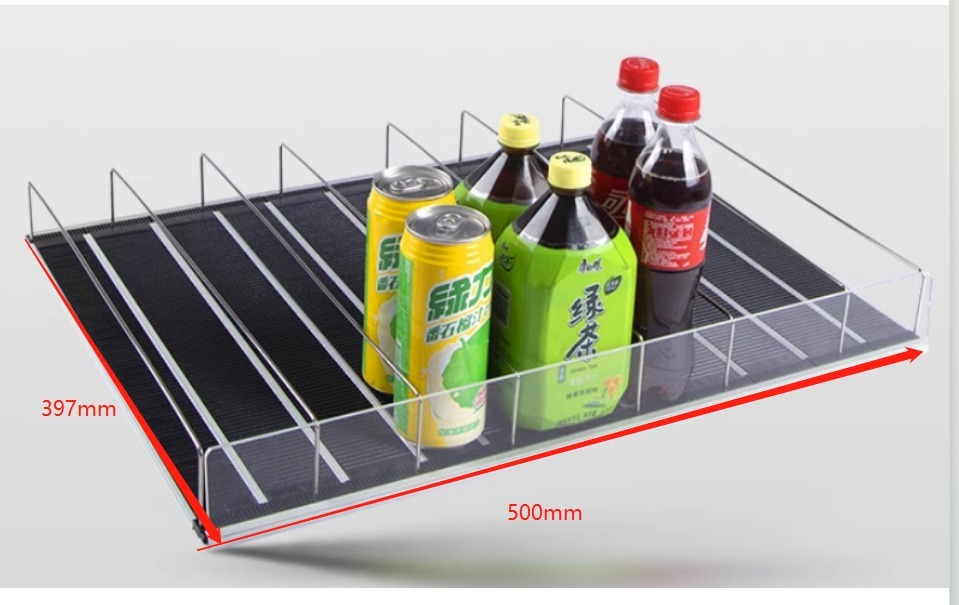

- Size and Configuration: Gravity roller shelves come in various sizes and configurations. Be sure to choose a shelving system that fits the available space and meets your storage requirements. Consider the width, height, and depth of the shelves to accommodate your products.

- Adjustability: Look for shelving systems that offer adjustable rollers or shelves. This allows you to customize the setup to accommodate different types of products, ensuring that your shelving system remains versatile and adaptable as your inventory changes.

- Durability: Gravity roller shelves are designed for frequent use, so it’s essential to choose a system made from high-quality materials that can withstand the rigors of a busy retail or warehouse environment. Look for shelves made from durable steel or other heavy-duty materials that are resistant to wear and tear.

Challenges of Gravity Roller Shelves

While gravity roller shelves offer many benefits, there are some potential challenges to consider:

- Initial Cost: Gravity roller shelves may have a higher upfront cost compared to traditional shelving systems. However, the long-term benefits in terms of labor savings, reduced waste, and improved efficiency often outweigh the initial investment.

- Maintenance: The rollers in gravity roller shelves may require occasional maintenance to ensure smooth operation. This may involve cleaning or lubricating the rollers to prevent them from becoming stuck or damaged.

Conclusion

Gravity roller shelves offer an innovative and efficient solution for businesses that require constant stock rotation and easy access to inventory. Whether used in supermarkets, warehouses, or pharmacies, these shelves provide a practical way to manage products while reducing labor costs and minimizing waste. With their self-feeding design, space optimization, and adaptability to various industries, gravity roller shelves are an essential tool for businesses looking to improve their overall efficiency and productivity.

As businesses continue to prioritize inventory management and cost savings, gravity roller shelves will remain a valuable asset in ensuring streamlined operations, organized stock, and enhanced customer satisfaction.