Innovative Gravity Roller Shelving: Efficiency is the lifeblood of any successful warehouse operation, and finding ways to streamline processes can lead to significant cost savings and productivity improvements. One such innovation that has gained popularity is gravity roller shelving. This system allows for faster stock rotation and easier access to products, making it an ideal solution for busy warehouses. In this blog, we’ll explore how gravity roller shelving works, its benefits, and how it can improve warehouse efficiency.

How Gravity Roller Shelving Works

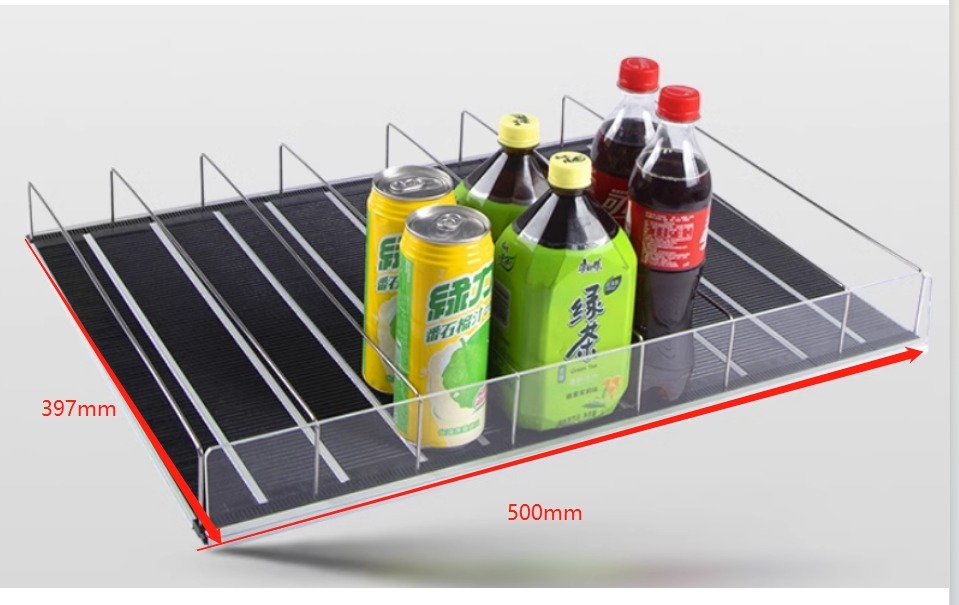

Gravity roller shelving systems, also known as flow racks, are designed to utilize the force of gravity to move products. The system consists of inclined shelves with rollers that allow products to roll from the back of the shelf to the front. As one item is removed from the front, the next item rolls forward, ensuring a continuous flow of products.

This “first in, first out” (FIFO) system is particularly useful for managing perishable goods, ensuring that older stock is always used before the newer stock is brought forward. Gravity roller shelves are often used in conjunction with conveyor belts or manual picking systems to streamline the picking and packing process.

Benefits of Gravity Roller Shelves

Improved Efficiency:

One of the primary advantages of gravity roller shelving is its ability to improve efficiency. By automatically moving products to the front of the shelf, workers spend less time searching for items and more time fulfilling orders. This can lead to faster picking times and increased productivity.

Reduced Labor Costs:

Because gravity roller shelving minimizes the need for manual product handling, it can significantly reduce labor costs. Workers no longer need to constantly rearrange stock, allowing them to focus on other tasks.

Better Space Utilization:

Gravity roller shelving systems make excellent use of vertical space, allowing warehouses to store more products in a smaller footprint. The shelves can be customized to fit the dimensions of the warehouse and can be easily integrated into existing storage systems.

FIFO Stock Rotation:

For warehouses that deal with perishable goods, the FIFO system is essential for preventing stock from becoming outdated. Gravity roller shelving ensures that the oldest stock is always used first, reducing the risk of spoilage and waste.

Increased Safety:

Gravity roller shelving systems are designed to be stable and secure, reducing the risk of products falling or being damaged during handling. The inclined shelves keep products in place while allowing for smooth movement.

Applications in Warehousing

Gravity roller shelving can be used in a variety of warehouse settings, from small distribution centers to large-scale manufacturing facilities. It is particularly useful in industries that require fast-moving inventory, such as:

- Grocery and Food Distribution: Gravity roller shelving is ideal for managing perishable goods that need to be rotated frequently.

- E-commerce Fulfillment: With the rise of online shopping, e-commerce warehouses require efficient picking and packing systems. Gravity roller shelving can help speed up the fulfillment process.

- Automotive and Industrial Supplies: Warehouses that deal with heavy or bulky items can benefit from the streamlined handling provided by gravity roller shelving.

Conclusion

Gravity roller shelving is a game-changing solution for warehouses looking to boost efficiency and reduce costs. By using the power of gravity to move products, these systems simplify stock rotation and make it easier for workers to access inventory. Whether you’re managing a small warehouse or a large distribution center, gravity roller shelving can help you optimize your operations and stay competitive in today’s fast-paced logistics environment.